Who first invented the flat glass manufacturing process, and when?

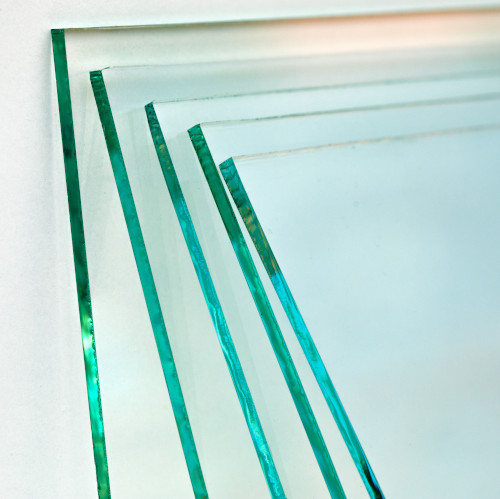

You probably haven't given much thought to how glass is produced. In fact, the float glass required for uses such as shop windows, cars and mirrors is very difficult to turn into float glass. Or at least it was before Sir Alastair Pilkington (1920-1995) developed the process of producing flat glass in the UK in 1959.

The flat glass was first produced in France in the 17th century. Flat glass is first melted; Then it is poured into molds and passed between rollers, thinned and flattened with the help of polishing and grinding processes. However, it is very difficult to obtain a perfect glass with this method.

Sir Lionel Alexander Bethune Pilkington OBE FRS (7 January 1920 – 5 May 1995), known as Sir Alastair Pilkington, was a British engineer and businessman who invented and perfected the float glass process for commercial manufacturing of plate glass.

Alastair Pilkington worked as a Technical Engineer for glass manufacturer Pilkington Brothers (whose name is a coincidence, by the way) and it took him seven years to perfect his technique for making flat glass. Prior to this, the plating process was used, developed in 1848 by the English engineer Henry Bessemer. But this process was an expensive method. Because the plating process caused the glass to deteriorate and scratch, these defects on the glass had to be corrected by polishing.

In flat glass production, a molten glass mixture traditionally composed of silica, sodium carbonate, calcium oxide, magnesium oxide and aluminum oxide is poured into a bath of molten tin. This results in the formation of a perfectly smooth glass strip on both sides, equal to a flat thickness of 6.8 mm. This glass strip makes it possible to stretch a thinner glass or vice versa, to form a thicker glass by stretching as needed. It is progressively cooled through the tin bath and then heats treated in a long furnace called a lehr. This is necessary because if the glass is cooled faster than necessary, the pressure on the glass will increase even more, causing the glass to break under the cutters.

A flat glass line can be around 500 meters long and produce 6,000 km of glass per year. Thanks to this innovative method, 970,000 tons of flat glass is produced every week in 370 flat glass factories around the world.