He received little education, grew up with Edison: Who is Edward Goodrich Acheson?

He received little education and earned his living by ordinary work until 1880 when he began working in Edison's laboratory.

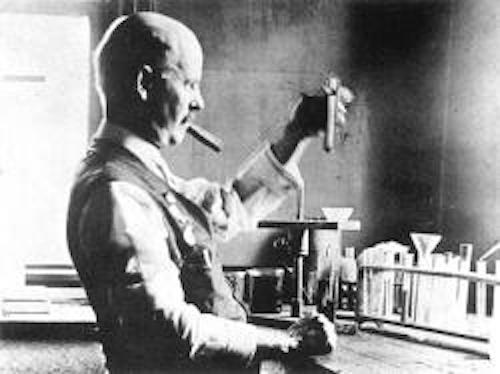

(1856-1931) US inventor and industrial chemist. He obtained the first synthetic abrasive and developed a method for producing artificial graphite. He was born on March 9, 1856, in Washington, Pennsylvania. He received little education and earned his living by ordinary work until 1880 when he began working in Edison's laboratory.

In those years, a team of about 50 people in Edison's laboratory was trying to develop the incandescent lamp. In 1881, the desired result was achieved and the first power plant was put into production in New York. In the same year, Acheson was sent to Italy, France, and Belgium to build the first power plants in Europe on behalf of the Edison Company. Returning to the USA after completing his mission in 1884, he decided to work independently and began experiments to produce artificial abrasives in an electric furnace.

In 1891, he obtained silicon carbide, a very hard abrasive. Continuing his experiments on the same material, Acheson, who patented a total of 69 inventions with artificial graphite and various lubricants, continued the production of these materials in the factories he established for the rest of his life.

He died on July 6 in New York.

Towards the end of the 19th century, natural abrasives such as diamond, emery stone, and garnet were unable to meet the needs of the industry. In the same period, with the widespread use of the electric furnace, entrepreneurs began to look for ways to produce silicon carbide and aluminum oxide, the hardest of the artificial abrasives, in the electric furnace. Acheson, who embarked on experiments for the same purpose, established his facility in Monongahela City (Pennsylvania), thinking that he could obtain abundant and cheap electricity for production from the Monongahela river. In 1891, he heated a mixture of pure silicon sand and finely ground coke in a small brick-lined electric furnace between about 2000°C and 2500°C. While passing through the carbon electrode in the furnace, the electric current producing heat started a reaction that resulted in the combination of the carbon in the coke composition and the silicon in the sand's structure as SiC (silicon carbide). Acheson named these shiny, hexagonal SiC crystals first carborundum and then corundum, which deposited on carbon electrodes and were hard enough to scratch glass. To further improve this abrasive, which he patented in 1893, he added some sawdust to the mix. The pores formed by the burning of these chips in the furnace allowed most of the flammable gases in the mixture to evaporate. It is the hardest of the known abrasives after carborundum, diamond, and boron carbide, which was used only for polishing precious stones because of its very high cost in the beginning. Today, silicon carbide, which is produced by a method similar to Acheson's method and under different trade names, is used in the processing of the hardest metals.

Later, Acheson, who increased the temperature of the furnace to examine the effects of high temperature on carborundum, saw that the silicon in the composition evaporated towards 4150″C and the remaining carbon crystallized into pure graphite. In 1896 he patented this method of producing artificial graphite. Graphite is an oily, soft, and conductive material; It is used in many fields from pencil making to the electrical industry, from making lubricants to reaction retarding rods in nuclear reactors. Artificial graphite production has been an important step since it is only found in certain regions in nature.