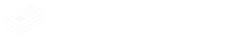

The man who turned cast iron into steel: Who is Henry Bessemer?

The Bessemer method, which greatly reduced the production cost in the iron and steel industry, was adopted in many countries in a short time, and he made a great fortune with the factories he established.

(1813-1898) English inventor and industrialist. It brought a new breakthrough to the 19th-century steel industry with its cost-reducing method of converting cast iron to steel. He was born on January 18, 1813, in Charlton, Hertfordshire. He left his education unfinished to work in his father's type foundry. In 1830, he opened his own workshop and switched to bronze plating and the production of light metal alloys. Bessemer, who started to produce the products of his creativity at a very young age, presented many inventions to the Royal Academy when he was only 20 years old. While the Bessemer method, which greatly reduced the production cost in the iron and steel industry, was adopted in many countries in a short time, he also made a great fortune with the factories he established in Sheffield. He received the title of "Sir" in 1879 and died in London on March 15, 1898.

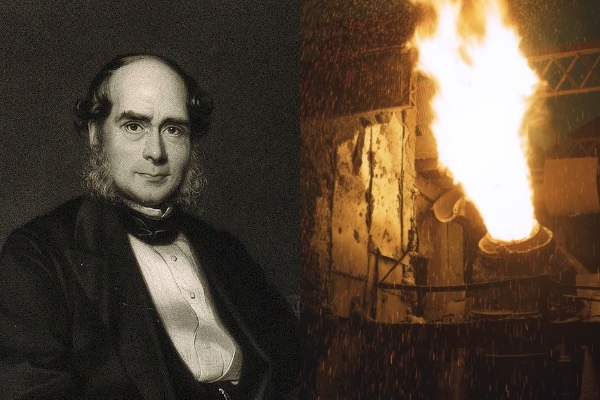

Bessemer started research in order to produce a harder iron alloy than known after a ball project he developed in 1854 was rejected on the grounds that it could not be realized with the metals and alloys of that day. At the beginning of the century, the steel obtained by melting iron ore with charcoal in Catalan furnaces was both limited in production and very costly. In the newly started blast furnaces, only cast iron (pig) could be obtained, and the cost increased even more as a second furnace was needed to convert it to steel. Bessemer was designed to blow air into the molten iron to reduce the percentage of carbon in the cast iron to convert it into steel. In 1855, he blew the cast iron he had melted in a fixed crucible with a blower from the side and succeeded in obtaining low-quality steel without using any other heat source. He patented his invention by announcing it in 1856. Cast iron makers, hoping that this method would provide labor and fuel economy, went into production but failed to produce usable steel.

Frustrated, Bessemer began investigating the causes and remedies for this unexpected failure. In the end, with the help of two steel producers operating under their own licenses, the reasons for the disruption were understood. Iron ores in England had plenty of phosphorus in their composition, and the air blown into the cast iron loaded the alloy with oxygen, and these two additives increased the brittleness of the steel.

Bessemer and his partners, who started to produce steel in the factory they established in Sheffield in 1858, started to use non-phosphorus sprouts they brought from Sweden to overcome this problem. Two years later, Bessemer developed the "Bessemer converter", in which liquid cast iron is treated with air forced from the bottom. But it had largely lost the support of the steelmakers. In 1879, the new method developed by Gilchrist and Thomas, which allowed the conversion of scrap iron into steel, dominated the British steel industry. In this industry, the Bessemer method was used for many years in some European countries, which are not as advanced as England, and in America.

Although Bessemer's method has become history, leaving its place to new methods, it has been a factor that accelerated the birth and development of the steel industry.